Gate Operators, Driveway Gates & Controls

Installation - Repair - Parts

Just need a Remote, Keypad or Gate Operator for a DYI project

Need help layout out and installation the project?

Text Joe at (479) 903-9993

Gate Operator Repair and Installation for Rogers, Bentonville, Springdale and all of NWA Call at (479) 903-9993

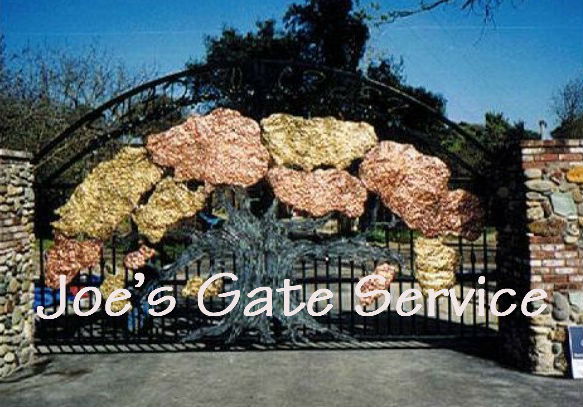

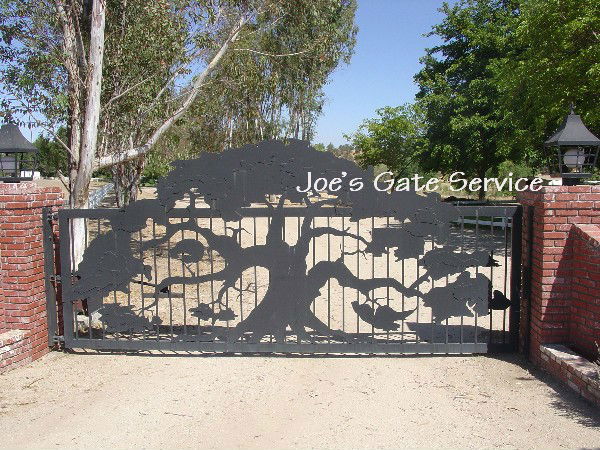

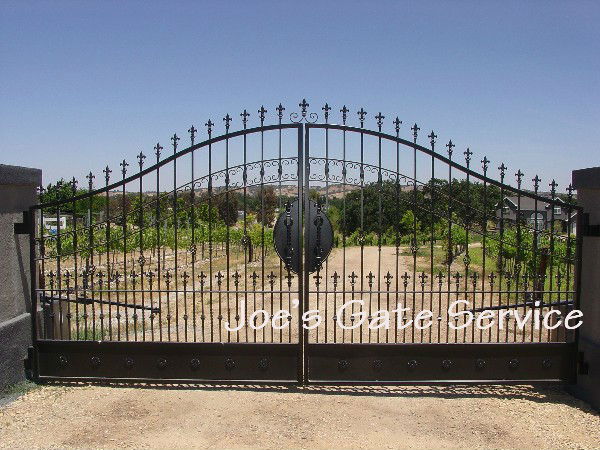

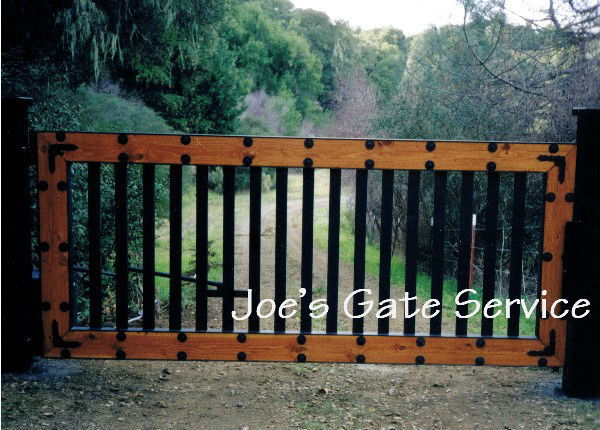

Check Out Our Gallery below

NOTE Joes Gate Service / NWA Gates & Controls

Contact

Parts

Text Joe at (479)903-9993 or e-mail below

SOS Fire Access System $275.00

Safety Photo Eye $65.00 https://www.paypal.com/instantcommerce/checkout/undefined

Visit our store at https://www.gatecontrolsonline.com

Safety Photo Eye $65.00 https://www.paypal.com/instantcommerce/checkout/undefined

Visit our store at https://www.gatecontrolsonline.com

Projects

Walmart Print Solutions

Walmart Print Solutions Bentonville

Maximum Gate Operators / Loops Cut-In

Ozarks Coca-Cola

Coca Cola Lowell

Installed Maximum Gate Operator

Black Hills Energy

Black Hills Siloam Springs

Gate Operator, Loops , Card Access

Salter Constrution

Palisades at Pleasant Crossing

Installed (8) Gate Operators, Loops, Gates

Liftmaster LA 500 Custom Gates

Custom Gates

Installed Gate Operators, Loops, Gates

Springdale Police Station

Gate Operators

Installed Gate Operators, Loops

Matrix Racquet Club

Gate Operators

Installed Gate Operator & Gate

NWA Pool & Spa

Gate Operator & Gate

Installed Gate Operators, Loops

F.A.Q

What should you consider

Installing automatic electric gates is not that easy. It is a really complicated process and this is why it is extremely important for the future owners to know what they will use the gate for. They should thoroughly explain to the technician what the purpose of that gate will be so that the technician could recommend the most suitable gate for them. The future owners will also have to choose between different materials, styles, colors, types of automation and ways of opening. There should be a safety check done by the technician before the gate is installed so that the technician could know if the gate is suitable for the given conditions.

Most common problems with automated gate openers

1.Problems due to cold weather and low temperatures

There are several problems your gate might experience when the low temperatures strike. You might notice some delay in opening of your gate, or even the inability to open at all.

Metal components will contract as the temperature drops and unless you are using grease specially intended for lower temperatures, the grease will thicken, too. All this makes it harder for the gate to move and open since it requires more power.

Another problem is the battery since it is inside a metal box. Due to this, as the temperature gets lower outside, the internal temperature of the battery will also drop and this will make it harder for the battery to start because of the reduction of the electro-chemical reaction. This reaction is meant to produce the electrical current which allows the gate system to operate. You may have noticed that if you try to open it a couple of times, it will finally work.

What happens here is very similar to what happens to your car when it is cold outside. When the engine won’t start because it is too cold outside, you can turn on your headlights for half a minute or a minute and then the engine will start. The same thing happens when you repeatedly try to start the engine. These actions create an internal resistance in the battery causing it to physically warm up from the inside, just enough to start the engine.

If you hear a clicking sound coming from your gate, that is the indication that the battery solenoid switch is trying to close, but it can’t because the power is too weak.

Luckily for all of us, there are several corrective steps that a person can take. If you follow the order of these steps, you will get an inexpensive solution to your problem.

This problem can occur in two scenarios.

Mechanical problems

There can be three causes for this problem

There are several problems your gate might experience when the low temperatures strike. You might notice some delay in opening of your gate, or even the inability to open at all.

Metal components will contract as the temperature drops and unless you are using grease specially intended for lower temperatures, the grease will thicken, too. All this makes it harder for the gate to move and open since it requires more power.

Another problem is the battery since it is inside a metal box. Due to this, as the temperature gets lower outside, the internal temperature of the battery will also drop and this will make it harder for the battery to start because of the reduction of the electro-chemical reaction. This reaction is meant to produce the electrical current which allows the gate system to operate. You may have noticed that if you try to open it a couple of times, it will finally work.

What happens here is very similar to what happens to your car when it is cold outside. When the engine won’t start because it is too cold outside, you can turn on your headlights for half a minute or a minute and then the engine will start. The same thing happens when you repeatedly try to start the engine. These actions create an internal resistance in the battery causing it to physically warm up from the inside, just enough to start the engine.

If you hear a clicking sound coming from your gate, that is the indication that the battery solenoid switch is trying to close, but it can’t because the power is too weak.

Luckily for all of us, there are several corrective steps that a person can take. If you follow the order of these steps, you will get an inexpensive solution to your problem.

- Disconnect the cables from the battery and then clean the ends of the cables, as well as the battery terminals.

- If your battery box is made of metal, then you should take some Styrofoam insulation and apply a thin layer of it onto the bottom and the sides of the box.

- Look at the solenoid switch and its electrical connections. You should look for corrosion and if you happen to find any, you have to clean the terminals.

- Take care of the rollers and bearing surfaces. You will have to clean them and then apply grease which is specially meant for cold weather. You can find this type of grease in any store for automotive parts.

- You should check the trickle charger and make sure that it is charging properly.

- If all these steps did not help you and you still notice problems with the working of your gate opening mechanism, then I suggest you to take your battery out and take it to an auto parts store to be tested under load. There they will tell you if you need to buy a new battery or not. If it happens so that you need a new one, make sure you buy a battery which is rated for “High Cold Cranking Amps” and not the “Deep Cycle battery” because these “High Cold Cranking Amps” batteries are designed to provide maximum amperage for a short period of time, even when the battery and the weather is cold. “Deep Cycle battery” is meant for long continuous small amperage loads. This battery could be used on electronics on recreational vehicles or on boats and for lights.

- First you should check if the breaker and the switch are working properly.

- Check the outlet in which the gate is plugged. You can use some other device to see if they work when plugged in the same outlet.

- Then look at all your outlets to see if their ground fault interrupter is tripping. You have to check all of them because if GFI is tripping this action will cause power to be cut from any device in the GFI’s circuit.

- The problem might be the remote controller, maybe it’s broken, the batteries are dead and need replacement or it has run out of its “working hours”.

- If your gate doesn’t stop where it is supposed to it is mainly due to the limit switch nut or cam failing to hit the limit switch at the designated time. If you have a slide gate you’ll notice that a lever is holding the limit nut in place. It’s riding inside the slots of the limit nut. To solve this problem you have to press it back out of the slot on the limit shaft. This will put it back in its correct place.

- Newer operators are programmed through the control board, check your owners manual.

This problem can occur in two scenarios.

- One reason might be the antenna which was cut or just shortened. Try to put it as high as you can and be careful not to let it touch any other metal surface.

- The other might be that some other source of transmitting is interfering with your source. Check to see if there is any possible source of radio transmitting near where you live. This could be a radio station, a military base, a flight path or an airport. If it happens that you do have these sources near you, then you will have to get a special receiver and an antenna.

- Check the face of your receiver cover. It is common that gate openers have separate receivers. Look for the names like Multi Code, Liftmaster, Linear and Mega code. Check your remote clicker because it will have the same name as the receiver cover does. While pressing the remote you should listen and wait for the click coming from the rec receiver.

Mechanical problems

- Check to see if there is something blocking the gate physically. Check the wheel bearings to see if they are broken and check the chain and track too to see if they is any visible damage on them. For a swing gate you should check the gate arm for damage, as well as the hinges since they could be stuck or even broken.

- If you still can’t find the cause then do the next thing. After making sure that the power supply is off, detach the chain for a sliding gate or detach the gate arm for a swing gate. Now try to move the gate to open/close it. If it can be done it means that there is nothing mechanical causing the problem. If you can’t move it means that there is a mechanical issue involved and that it would be smart to call a professional technician.

- First check to see if any of the other house residents have maybe entered the “hold open” command and you didn’t know about this.

- Then you should check for the key switch. Maybe the corrosion took its toll on the electrical switch on the back of the key cylinder, or the fire department came to your house without you knowing it to test the fire department key switch and they simply forgot to put it back to its regular operation.

- This problem can also occur when devices like the photo eye or any other are preventing the gate from closing. You can check to see if the photo eye is working properly. First check to see if the safety LED light is lit. You should find this light on the opener control board. Look at the reflector if you have one. Maybe it is misaligned or even wet. By waving your hand in front of the photo eye, you will find out if it is working properly or not. The clicking sound means that everything is in order. Sometimes insects can cause malfunction of the photo safety sensors and control boxes since they prefer warm places. You should check from time to time and clean them with a dry cloth.

- You should check the edge transmitters. These will be found on the gates with reversing edges. There could be a battery issue which means you will have to change the battery. Make sure you buy the right type of battery depending on the type of your edge transmitter. If there is nothing wrong with the battery, then the problem is the transmitter itself. The corrosion might have gotten to it or if it might be damaged in some other way. You would have to replace that transmitter with a new one if this is the case.

- You should use the breaker to cut all power off. This action will automatically cause the gate to be released. Make sure to look at the loop detectors when you turn the motor on. The lights on the loop detector will tell you if you have a loop problem. It is possible that something is putting pressure to the loop too. If the lights are lit red, then you’ll know that you have one of these two situations on your hands.

- The best way to get your gate fixed is certainly to call us for repair

- This is not a rare problem with sliding gates. Usually, the common cause of this problem is some kind of blockage on the gate track. A number of things can be the blockage. Stones, papers, bags, pieces of other materials and objects. This can be easily cleaned with a broom. Check the rollers to see if they are in a good condition and working properly. There might be something stuck in them too.

- If you happen to have a swing gate, then you have to check its joints to see if the lube has worn off. After doing this, you should make sure that the level of the gate is correct. You will do this by disconnecting the gate from its power source. Observe its behavior. It should sway evenly.

- As on any remote controllers, there is a little red light on the top part of it. This light will be lit when you give a command to the gate to open or close. If the light didn’t lit up when you pressed the remote key, then you problem can either be the batteries or the life span of the controller. Try changing the batteries with the new ones. If the problem continues after you have replaced the batteries then it is obvious that you need to buy a new remote controller since the old one has probably run out of its “working hours”. You can call a technician or a supplier from who you bought it. The technician will program the new remote controller and your problem will be solved.

- There will be situations when you will have to put your gate into manual mode. You may experience a power outage or your gate isn’t working because it’s broken or you forgot to do an annual service and it’s showing difficulties in its operating. If the power is off this mode will allow the gate to open and close. You should have a manual release key in your possession and the gate should have been tested to see if it works in manual mode.

There can be three causes for this problem

- The first one is because the remote controller is broken, its batteries are dead and they need replacement or it’s just run out of its “working hours”.

- Then it could be your ascending driveway’s fault. If this is the situation you are in, then either make the gate open to the other side if it’s possible or just hang the gate to a higher post so it doesn’t reach the driveway as it opens.

- Since the gate safety loop sensor or photo eye is present at most gates, you should check it to see if this sensor is the cause of malfunction. It is made to prevent the gate from harming any person, animal or object that might be on its path. If the sensor notices an obstacle it reverses the gate process/disables it. If the sensors aren’t working properly, you should call us.

- If your gate keeps beeping, especially during the night after the storm and making battery low sounds, you should try to add one more battery, that is, more power. It is possible that after the storm your battery might make sounds as if it is dead but the next day everything will be fine.

- Photo eye might also send a beeping sound if battery is low.

Most common problems when installing a automated gate operator

Ten Problems before installing a

- The gate does not work manually. Before turning your gate into an automated gate, you have to make sure that it can work normally in a manual mode. If it shows any signs of irregular working process, these problems will not just disappear when you turn it into automated gate.

- Avoid installing automated gates on ascending surfaces. This position of the ground surface will put a lot of pressure on the automation and you will have to buy some more equipment to make it work. It isn’t impossible but if you can avoid it, I suggest that you do so.

- Using the wrong equipment. Never use the equipment which is not specified by the manufacturer of the gate! You have to buy the correct equipment because if you do otherwise and your gate malfunctions, you will not be able to file a complaint and your guarantee will no longer be valid. (see Gate Operator Classifications)

- Provide drainage if necessary. If your motor will be installed below the ground surface, you have to provide it with fitting drainage. If the water has nowhere to go, the motor will not function properly.

- Be responsible! Don’t try to install the gate yourself. If you save some money on not calling the professional for this job, it may end up in a disaster. There are licensed technicians who should install your gate and who will take legal risks of the installation. You don’t want to be taken responsible for a disaster which could have been avoided if you have just called the right person.

- Beware of the wind. If you are living in an area where there is a lot of wind, you would want to think before you pick your future gate. You should then definitely avoid close boarded wooden gates. ‘Open railing’ gate might be a better solution but even this gate will not work perfectly depending on the strength of the wind.

- Gate controllers. It is really important, as I have stated above, to explain to the technician how and what the gate will be used for. This way the technician will be able to provide you with the best solution for opening and closing of your gate. Choices you will have are: vehicle detectors, keypads or card access, radio remote controllers, ground loops or probe, GSM via your mobile phone or push buttons.

- Don’t forget about pedestrians and visitors. If you don’t have a separate entrance, you will have to think about the ways for pedestrian visitors to enter your estate. There must be a way of letting the household residents know that they are at the entrance. The best solution is usually an intercom. You can add a video camera too. .

- You have to provide access for regular visitors like postmen, gardeners etc. This can be done by a time clock which would decrease security measures on the gate at a specific time of the day and therefore allow specific personas to enter your estate in an easier way.

- Total gate security – If you want to be completely sure that is not possible to forcefully enter through your gate, think about adding some extra locks to the gate or if it is really necessary add some posts in front or behind the gate.

Gate Operator Safety

SAFETY TIPS For Gate Openers

Here are some helpful safety tips. This list is not intended to be a comprehensive list of every safety precaution. Always consult your manufacturer’s installation or instruction manual for safety information about your model. For more safety tips about automated vehicular gate systems, see our Automatic Vehicular Gate System Safety Guide

1. Stand Clear! Motorized sliding and swinging gates can be dangerous. When a motorized gate is opening or closing, stay clear of the motion of the gate. Entrapment can cause injury or death.

2. Look for the Listing Mark. For safety, make sure that the vehicular gate opener being installed on your property bears the “mark” of a nationally recognized testing laboratory such as “UL” or “ETL.” These marks identify that the product has been tested and complies with the UL 325 Standard for Safety.

3. Don’t Reach Through. Never reach through a motorized gate to operate the gate opener controls. Reaching through a gate to operate a control device is extremely dangerous. The UL Safety Standard for gate openers prohibits controls from being positioned within reach of the gate or gate opener.

4. 10-Foot Rule. Gate controls must be installed and positioned so that a person using the control cannot touch the gate or gate opener. As a rule of thumb, controls should be installed a minimum of 10 feet away from the gate. If your gate opener system allows a person to “reach through” the gate to operate the control, immediately shut off power to the gate system and contact a professional gate system company to move or disconnect the control.

5. Warn Children. Do not allow children to play on automated gates. This could be a deadly game. Take time to teach children about the importance of safety in the vicinity of an automated gate.

6. Inherent Reverse. Since March 2000, gate openers that are listed by a nationally recognized testing laboratory and are intended for use by the public (1) must include an inherent reversing feature and (2) must be installed with a secondary entrapment device such as photoelectric eyes or reversing edges.

Older automatic gates generally do not have these built-in sensitivity systems that can detect objects that may be caught in the gate. If your gate opener lacks this type of system that can detect obstructions in BOTH the opening and closing cycles, it’s time to replace your gate opener.

7. Do It Yourself? Installing a vehicular gate opener system is not a project for a do-it-yourselfer. Reason: gates are heavy, and these systems generate high levels of force that can create hazards if the system is not properly installed. Gate openers cannot be simply “plugged in.” They require detailed installation procedures, installation of secondary entrapment prevention devices, and installation of vehicular detection devices. They must also be installed in compliance with the UL 325 Safety Standard, and the gate itself needs to comply with ASTM F2200. If you need an automated vehicular gate system installed, contact a professional gate systems installation company.

8. Maintenance. Like all electro-mechanical devices, your automated gate system requires periodic maintenance and testing. Follow the recommended maintenance and testing schedule in your gate opener owner’s manual. Ask your professional automated gate system installer about a service contract to keep your gate system running safely and smoothly.

9. Know Your System. Ask your professional gate system company to demonstrate the safety systems associated with your gate opener. Make sure you know how to safely test these systems. It’s also important to know how to manually operate your gate opener in the event of a power outage or system failure.

10. Pinch Points! According to ASTM F2200, all exposed rollers in sliding gates must have covers or guards to protect pinch points. These covers prevent hands or feet from getting caught between the gate and the roller. If your sliding gate does not have roller covers or guards, contact a trained vehicular gate opener technician to have appropriate guards installed on your gate system

Here are some helpful safety tips. This list is not intended to be a comprehensive list of every safety precaution. Always consult your manufacturer’s installation or instruction manual for safety information about your model. For more safety tips about automated vehicular gate systems, see our Automatic Vehicular Gate System Safety Guide

1. Stand Clear! Motorized sliding and swinging gates can be dangerous. When a motorized gate is opening or closing, stay clear of the motion of the gate. Entrapment can cause injury or death.

2. Look for the Listing Mark. For safety, make sure that the vehicular gate opener being installed on your property bears the “mark” of a nationally recognized testing laboratory such as “UL” or “ETL.” These marks identify that the product has been tested and complies with the UL 325 Standard for Safety.

3. Don’t Reach Through. Never reach through a motorized gate to operate the gate opener controls. Reaching through a gate to operate a control device is extremely dangerous. The UL Safety Standard for gate openers prohibits controls from being positioned within reach of the gate or gate opener.

4. 10-Foot Rule. Gate controls must be installed and positioned so that a person using the control cannot touch the gate or gate opener. As a rule of thumb, controls should be installed a minimum of 10 feet away from the gate. If your gate opener system allows a person to “reach through” the gate to operate the control, immediately shut off power to the gate system and contact a professional gate system company to move or disconnect the control.

5. Warn Children. Do not allow children to play on automated gates. This could be a deadly game. Take time to teach children about the importance of safety in the vicinity of an automated gate.

6. Inherent Reverse. Since March 2000, gate openers that are listed by a nationally recognized testing laboratory and are intended for use by the public (1) must include an inherent reversing feature and (2) must be installed with a secondary entrapment device such as photoelectric eyes or reversing edges.

Older automatic gates generally do not have these built-in sensitivity systems that can detect objects that may be caught in the gate. If your gate opener lacks this type of system that can detect obstructions in BOTH the opening and closing cycles, it’s time to replace your gate opener.

7. Do It Yourself? Installing a vehicular gate opener system is not a project for a do-it-yourselfer. Reason: gates are heavy, and these systems generate high levels of force that can create hazards if the system is not properly installed. Gate openers cannot be simply “plugged in.” They require detailed installation procedures, installation of secondary entrapment prevention devices, and installation of vehicular detection devices. They must also be installed in compliance with the UL 325 Safety Standard, and the gate itself needs to comply with ASTM F2200. If you need an automated vehicular gate system installed, contact a professional gate systems installation company.

8. Maintenance. Like all electro-mechanical devices, your automated gate system requires periodic maintenance and testing. Follow the recommended maintenance and testing schedule in your gate opener owner’s manual. Ask your professional automated gate system installer about a service contract to keep your gate system running safely and smoothly.

9. Know Your System. Ask your professional gate system company to demonstrate the safety systems associated with your gate opener. Make sure you know how to safely test these systems. It’s also important to know how to manually operate your gate opener in the event of a power outage or system failure.

10. Pinch Points! According to ASTM F2200, all exposed rollers in sliding gates must have covers or guards to protect pinch points. These covers prevent hands or feet from getting caught between the gate and the roller. If your sliding gate does not have roller covers or guards, contact a trained vehicular gate opener technician to have appropriate guards installed on your gate system